Matt Dibbs, Managing Director Meteor Communications Ltd., explains how the Coronavirus pandemic presented significant challenges to the collection of environmental data. However, by utilising novel technology, British water companies and the Environment Agency have been able to continue gathering water quality data in locations from Cornwall to Cumbria. Matt believes that this provides a template for environmental monitoring on the future.

The Coronavirus pandemic presented significant challenges to the collection of environmental data. However, by utilising novel technology, water companies and the Environment Agency have been able to continue gathering key data in locations from Cornwall to Cumbria.

Water quality monitoring

The British Environment Agency and water utilities have statutory obligations to protect and enhance water resources; and in order to fulfil these obligations they undertake large numbers of measurements to establish baseline data, detect trends, monitor mitigation measures, and identify sources of pollution from both point and diffuse sources. This involves making a range of measurements; either collecting samples for laboratory analysis or employing portable instruments in the field. To support these activities, rapidly deployable, automatic, remote monitoring systems have also been developed to provide real-time access to data 24/7.

The Environment Agency’s Environmental Sensor Network (ESNET) is operated by the National Laboratory Service. This agile monitoring capability of over 150 sites is providing a template for sustainable, resilient, environmental monitoring. ESNET is comprised of modular water quality monitoring systems that can be quickly and easily deployed at remote sites. The telemetry modules and website capability are developed and supplied by Meteor Communications Ltd.

The laboratory analysis of samples is vitally important and allows industry and regulators to analyse for an extensive array of parameters. These samples inform a better understanding of longer term trends and facilitate the monitoring of trace and emerging pollutants. However, water bodies are highly dynamic environments. Precipitation, flow and the intermittent or diurnal nature of process and agricultural effluents mean that in some circumstances it is necessary to employ enhanced high-resolution monitoring techniques to provide evidence upon which informed operational and policy decisions can be made.

Real-time, high-resolution water quality monitoring systems

The Environment Agency uses two main types of continuous water quality monitors; a fixed, cabinet or kiosk based system (right), and a portable version which is housed in a rugged case (below). Evidence from these systems is utilised by environment planners, ecologists, fisheries and environment management teams across the agency. These continuous water quality monitoring systems have been developed and refined over the last 20 years, so that they can be quickly and easily deployed at almost any national location; delivering data via telemetry within minutes of installation. This high-intensity monitoring capability substantially improves the temporal and spatial quality of data. The rapid deployment of these monitors now enables the agency to respond more quickly to pollution events.

The Environment Agency uses two main types of continuous water quality monitors; a fixed, cabinet or kiosk based system (right), and a portable version which is housed in a rugged case (below). Evidence from these systems is utilised by environment planners, ecologists, fisheries and environment management teams across the agency. These continuous water quality monitoring systems have been developed and refined over the last 20 years, so that they can be quickly and easily deployed at almost any national location; delivering data via telemetry within minutes of installation. This high-intensity monitoring capability substantially improves the temporal and spatial quality of data. The rapid deployment of these monitors now enables the agency to respond more quickly to pollution events.

Each system is built around a battery-powered multi-parameter water quality sonde; situated in the river or located in a bankside flow-through chamber, with samples being taken at 15 minute intervals. Typically, the sondes are loaded with sensors for measuring parameters such as dissolved oxygen, temperature, pH, conductivity, turbidity, ammonium, Blue Green Algae and chlorophyll. Additionally, the systems can incorporate an automatic sampler which can be triggered when pre-determined conditions arise. This means that event-triggered samples can be made available for subsequent laboratory investigation.

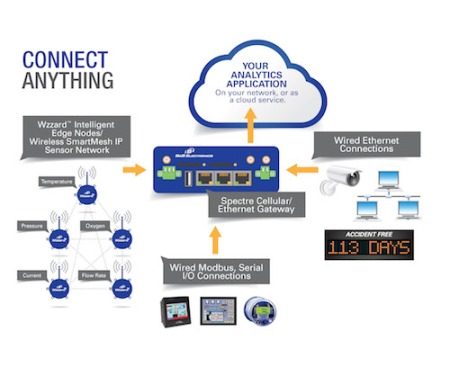

Measured data is transferred securely to the Meteor Data Cloud, where stakeholders access graphical, tabular and geospatial views to see live readings and retrieve recorded data. With this customisable data presentation, managers are able to communicate evidence in a form which is more accessible and meaningful to public representatives, interest groups and stakeholders. This also enables bodies such as the Environment Agency to promote the use of open data, providing live data links, advice and services to a diverse range of public groups and organisations such as flood awareness groups, rivers trusts and angling organisations.

During the coronavirus pandemic the Environment Agency collected over 16,000 samples per day using ESNET and the cloud-based viewer was made available to all water quality practitioners across the Defra family, as well as a wide range of external bodies.

The advantages of remote monitoring networks

By collecting data automatically; the volume of evidence increases dramatically, furthermore, such systems are resilient to the effects of issues such as a lockdown; because monitoring practitioners are able to collect and assess data; even if they are isolated at home.

In recent years, sensors and water quality sondes have undergone significant development to improve reliability and extend the period between service and calibration. Meteor Communications provides a comprehensive maintenance program for customers on a monthly basis and freshly calibrated units are constantly in circulation within the ESNET system.

Continuous monitoring enables the detection of transient spikes that can arise from pollution incidents; helping to raise timely alarms and identify ongoing sources of pollution. This evidence can be used to develop informed interventions by stakeholders in industry and agriculture, and to enable the adoption of practices that improve water quality.

Integrated systems such as those operated in the Thames Valley catchment are able to track pollution events as they move with the river, which means for example, that water treatment plants can adjust their intakes accordingly.

Tidal water presents a major monitoring challenge because large volumes of saline water are constantly moving back and forth, which significantly complicates the comparison of measurements at one point on the river. So, for example, a measurement at one location at 9am is not directly comparable with another measurement at 9am a week later, because one might be taken at low tide and the other at high tide. The transient effects of CSO’s and algal activity further complicate the picture. Water quality scientists at the Environment Agency have therefore worked closely with Meteor Communications to develop a software-based monitoring system, known as ‘Half Tide Correction’ (HTC). In simple terms, this corrects for the effects of the tide and allows assessment of the underlying water quality.

Continuous, accurate and robust data allows managers to assess the impact of developments and remediation measures. Good data, used as evidence, informs the evaluation of investments and leads to better decision making.

The ESNET network also provides image acquisition, and the Environment Agency and others have deployed over 600 ESNET camera sites. These remote cameras are used to continuously monitor a wide range of flood defence infrastructure and assets; rapidly detecting blockages or overflows and avoiding the need for unnecessary and costly site visits.

ESNET systems also provide an essential tool for measuring the effectiveness of Natural Flood Management (NFM) schemes. In Oxfordshire for example, working with a wide range of partners in the Evenlode catchment, the systems are helping to evaluate the effectiveness of NFM measures for the local community and other stakeholders.

Utilities – final effluent monitoring

The flexibility of the ESNET systems makes them ideal for monitoring water quality at waste water treatment works. The responsibility for monitoring discharges rests with the operators themselves under the terms of operator self-monitoring (OSM) agreements. OSM is now delivered by a spot sampling regime supported by real time monitors, so an opportunity exists for all stakeholders to benefit from the advantages of continuous monitoring.

A British water company is now operating 130 ESNET final effluent monitoring systems across their business. These sites have continued to operate during the COVID-19 lockdown providing operators and managers with vital data with which to assess performance and compliance during this challenging period.

Summary

Recent advances in technology have enabled the development of continuous monitoring systems that are quick and easy to install. The portable ESNET system is routinely commissioned in less than an hour, and the pumped kiosks can usually be installed within half a day.

With little or no capital works necessary prior to the installation of an ESNET system, continuous, easily accessible, multi-parameter data can be established quickly and cost effectively. Real-time monitoring means less travel, less time on site and a lower carbon footprint. Real time data can also be provided to stakeholders, timely alarms triggered and monitoring can continue unaffected by the impact of viral pandemics.

Posted by Eoin Ó Riain

Posted by Eoin Ó Riain